Mitigating Concerns Over Subvisible Particles

Subvisible particulates (defined as those in the 0.1-10 micron range) are a growing concern for injectable drug manufacturers. The particles may cause aggregation, which can impact the drug product and create a potential safety risk for the patient. To help ensure product quality, the U.S. Food and Drug Administration recommends that manufacturers gain a better understanding of how subvisible particles impact the drug.

![]()

Manufacturers should be aware of what types of subvisible particles can be found within the drug product, and should complete chemical characterization of those particles. Also, the origins of the particles should be known: is the particle from the environment, part of the manufacturing process, a reaction byproduct or coming from the container closure system?

As manufacturers begin to understand the subvisible particles affecting their product, they will gain a better understanding of the possible impact to the drug product and the patient, as well as the origin of the contamination.

New elastomer formulations made using cleaner and fewer ingredients have improved component quality. However, a deeper process understanding can help to mitigate risk during the manufacturing process. West has incorporated holistic Quality by Design (QbD) into some of its manufacturing process, and by doing so, is now achieving the highest possible process understanding. Such knowledge lends itself to increased process stability, which corresponds with an increase in quality for packaging components.

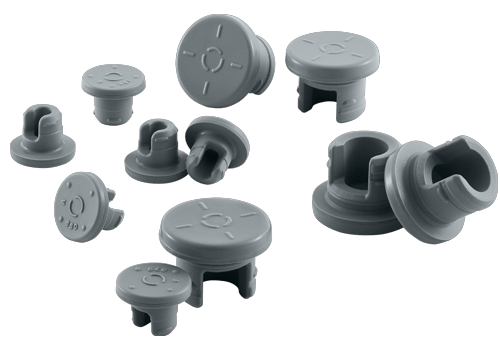

In 2012, West introduced a product line for elastomeric closures – NovaPure® components. Based on the QbD concept, the NovaPure brand was developed using a comprehensive quality target profile based on the needs of customers and patients. Critical quality attributes, determined with the end user in mind, have been built into the development process to help ensure quality, safety and efficacy throughout a drug product’s lifecycle. By following QbD principals, the West process provides a new, unrivaled level of component quality including a sub-visible particle specification supported by data and science-based decision making.

NovaPure® is a registered trademark of West Pharmaceutical Services, Inc., in the United States and other jurisdictions.