Coring and Fragmentation of Elastomer Components – Some Fundamentals

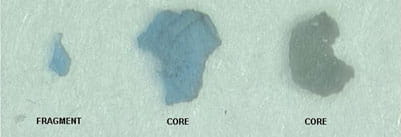

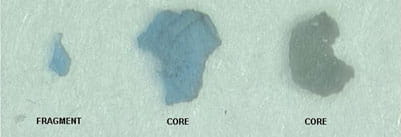

The coring and fragmentation of elastomer components used in containment of parenteral drug products continues to be a challenge. Many factors influence these phenomena, so it is critical that a pharmaceutical manufacturer understands how a vial system will be used, for example: what is the recommended needle gauge; is it single- or multi-dose; could spikes, vial adapters or closed system transfer devices be used. Cores and fragments can be generated by needle penetration of the elastomer components. Cores are formed by the needle cannula cutting the elastomer – ordinarily they are cylindrical. Fragments are formed via an abrasion phenomenon of the needle penetration – shapes are irregular.

![]()

Properties of both elastomer and needle affect coring and fragmentation. Based upon West experience, risk factors are:

Elastomer

- Formulation: natural rubber and isoprene have higher tensile strengths and more robust functional properties than butyl – and thus have reduced risk of coring

- Configuration: thinner stopper diaphragms generally have reduced risk of coring

- Siliconization: unsiliconized components may have increased risk of coring

- Component Processing: excessive processing, particularly high level of gamma irradiation, may cause degradation and increase risk of coring

- Hardness: harder formulations may have increased risk of coring, especially when sterilization process or needle type is not optimized

Needle

- Type: blunt needle tips have a much higher risk to cause fragmentation, as compared to sharp beveled needles

- Gauge: needles larger than 21-gauge have increased risk to cause fragmentation

- Siliconization: low-level, or inconsistent, siliconization causes increased risk of coring and fragmentation

- Reuse: reuse will blunt needle tips, remove siliconization, and thus increase risk of coring and fragmentation.

- Force and Angle of Puncture: higher needle insertion forces increase risk of coring, as does needle insertion at 45° to the plane of the component

- Number of Punctures: multiple stopper punctures greatly increase risk of coring

- Incorrect Use: using a spike on a stopper design not so intended increases risk of fragments

- Quality: it has been noted numerous times that poor quality (e.g., irregular tip, improperly formed) can result in cores and fragments

To select the right elastomer component, based upon performance and function, reach out to West Technical Customer Support (TCS) for assistance.