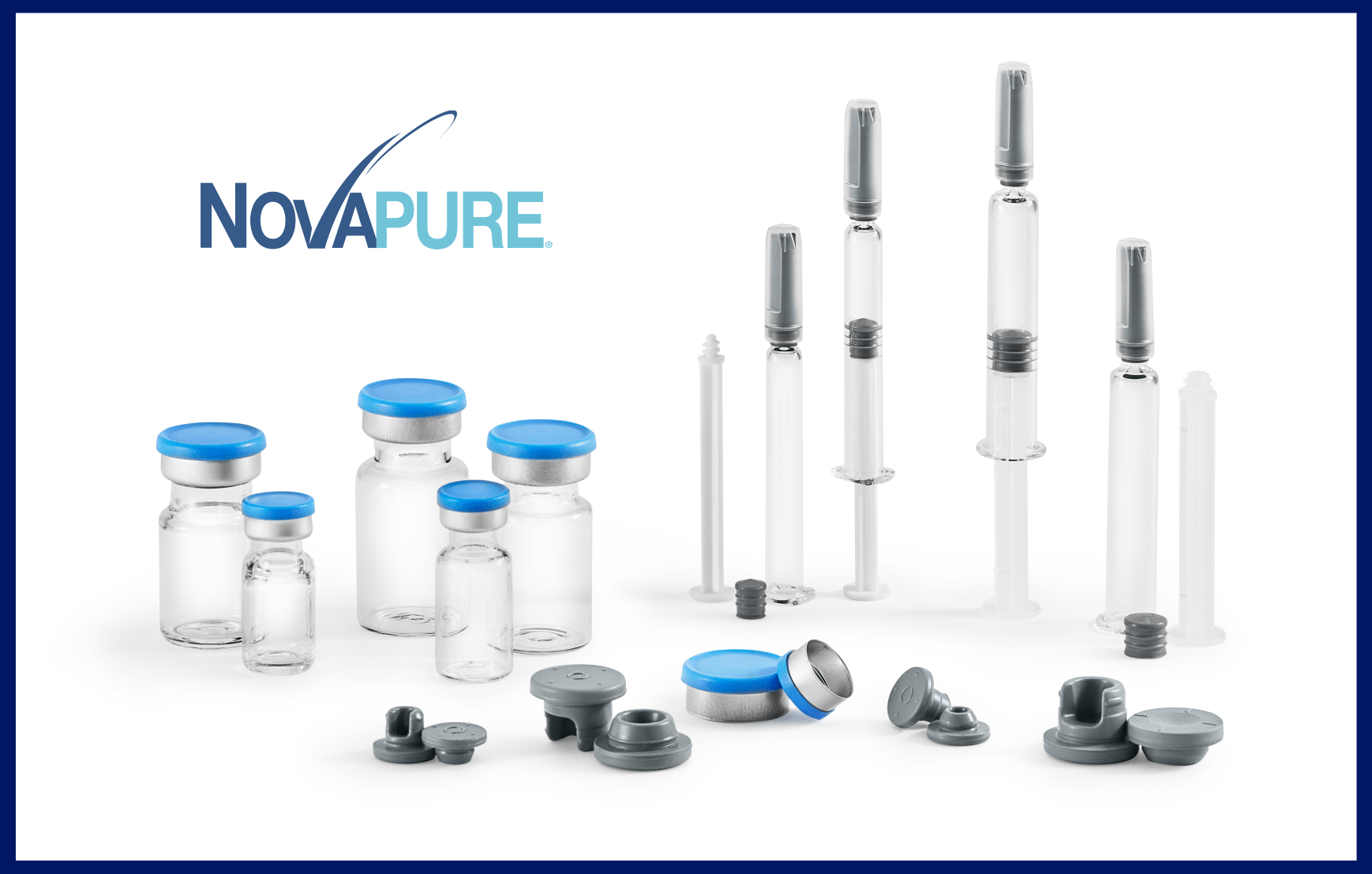

Challenges: Traditional packaging solutions may fall short on complex molecules

Drugs are becoming increasingly complex, requiring extra protection and higher quality and performance standards than traditional packaging components. By using existing package with your new drug, you may experience issues such as inconsistent performance, malfunctions, container closure integrity failures, or slower injection rates. In addition, quality expectations continue to increase, and regulatory requirements are more stringent and faster evolving than ever. Packaging you used successfully in the past may not meet the rising standards. By continuing to approach packaging in this way, you may risk delaying your launch, losing first to market advantage, failing your patients, and falling short of revenue and market share expectations.

)

)