Designing Robust Studies to Meet Auto-Injector Performance Requirements

In many instances, injectable pharmaceuticals need to be administered by patients or their caregivers rather than by healthcare professionals. While it is convenient to receive treatment at home without having to travel to a healthcare facility, the notion of administering drug injections, or even the sight of needles, can be intimidating to many individuals. The process can be greatly simplified with the use of auto-injectors. These devices typically contain a drug-filled syringe and make the injection procedure more straightforward by semi-automating the process.

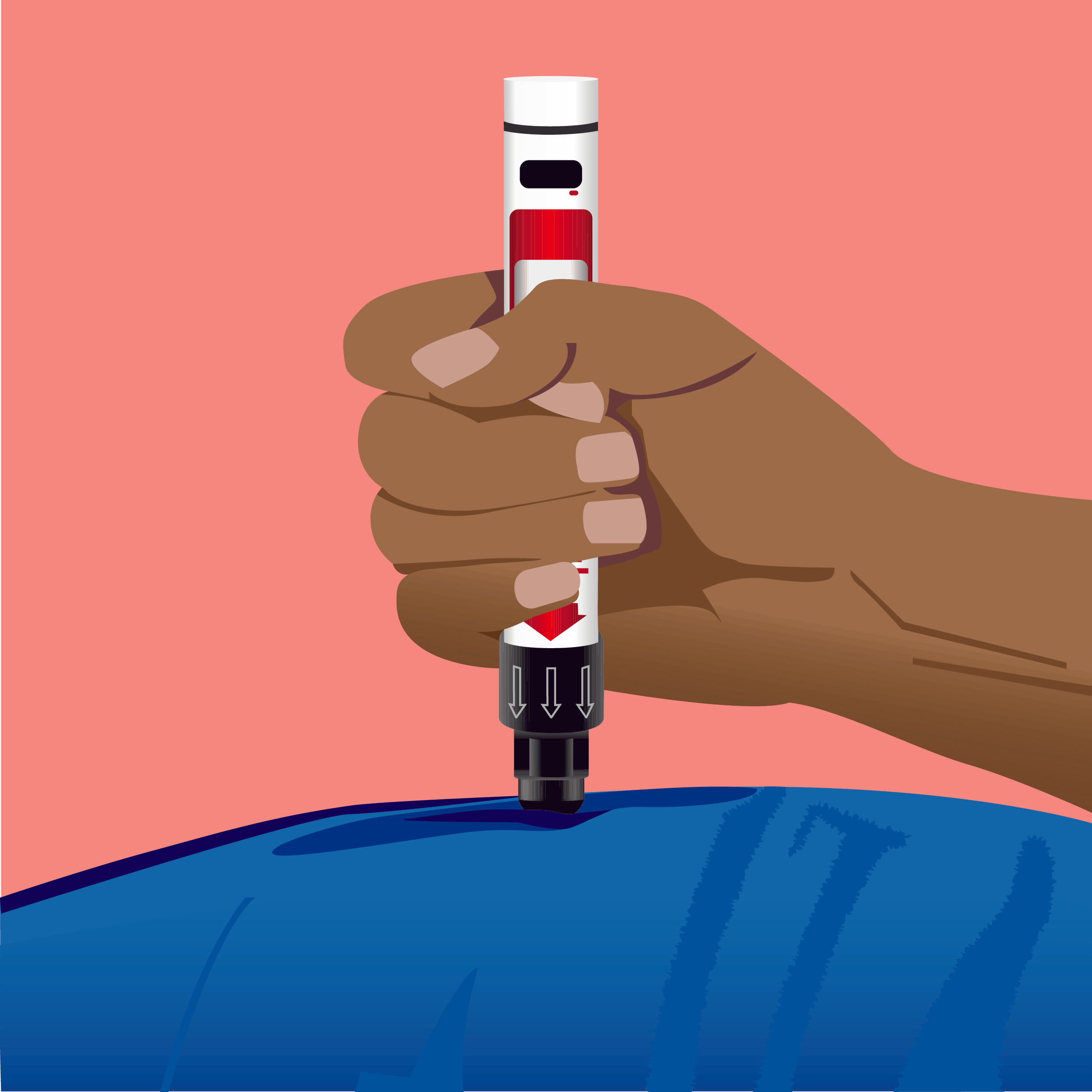

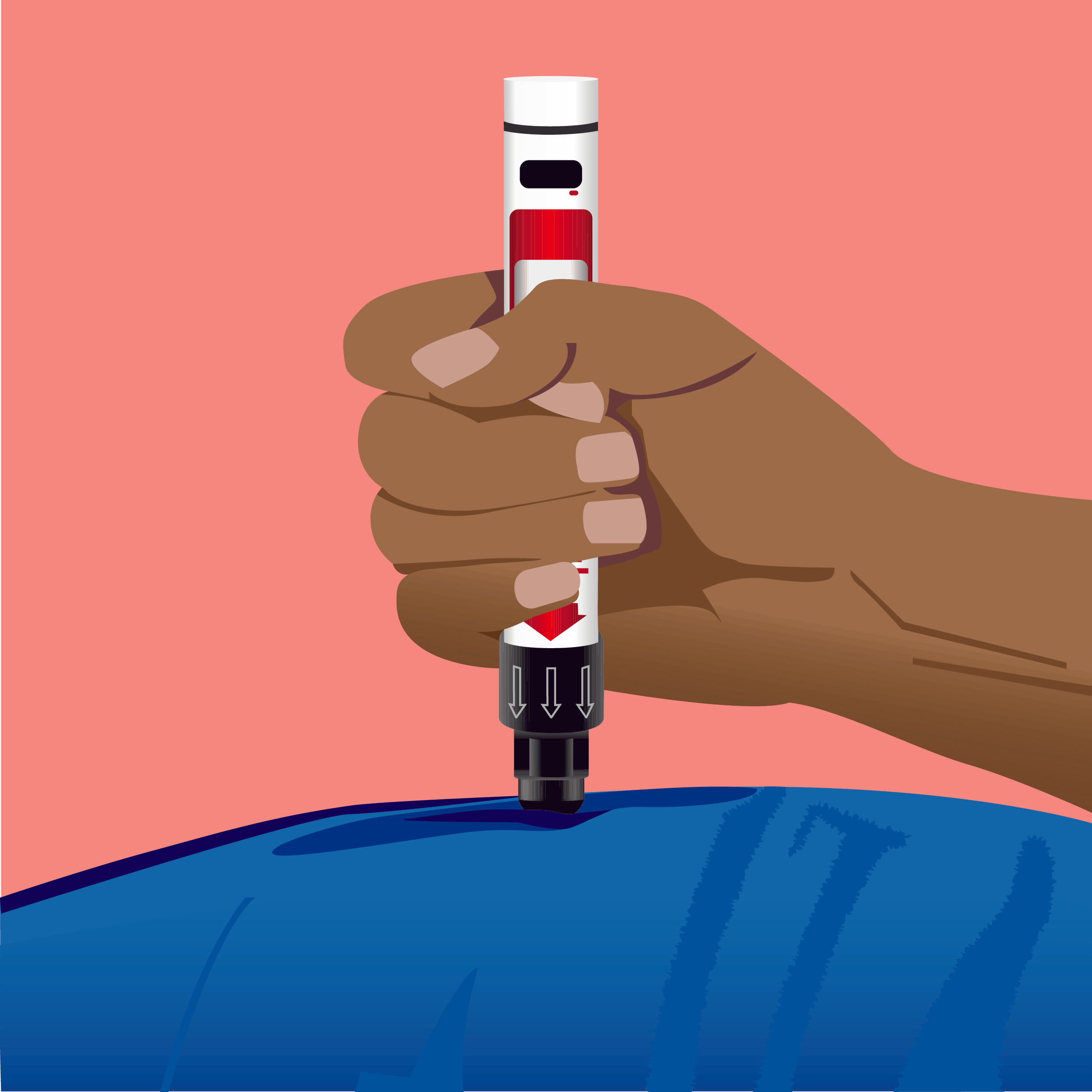

To administer the drug, the user first disinfects the skin where the injection is to be performed using an alcohol wipe. The user then removes the cap from the end of the auto-injector and presses the auto-injector tip against the skin at the injection site, which activates the auto-injector to administer the drug through a spring-loaded actuator. Once the injection is complete and the user moves the auto-injector away from the skin, the needle shield is engaged, and the needle is safely hidden away. As a result, the injection is administered without the user ever seeing the needle or worrying about the injection procedure.

Auto-injectors can be used for a variety of applications, ranging from emergency use to treating chronic conditions1. Their regulatory approval guidelines are described in an FDA guidance document2. Performance testing of these combination product devices, filled with their intended drug product, is primarily advised by ISO 11608-5:2022 Needle-based injection systems for medical use — Requirements and test methods — Part 5: Automated functions3. The 2022 revision of the ISO 11608 series of standards refocuses on the performance of the primary functions of needle-based injection systems4. Primary functions are those functions whose failure would cause failure of the device to “accurately deliver the medicinal product via the correct route,” and/or to “directly result in unacceptable harm to the patient.”

The critical tests for ensuring the proper performance of the device include:

- Cap Removal Force According to ISO 11608-1:2022, “failure to meet cap removal force specifications could delay the treatment… [which] could result in an unacceptable harm to the patient.” As a result, meeting these specifications is a primary function of the device. A cap removal force which is too low could result in the cap falling off during shipping and handling and result in product contamination or product loss. A cap that is too hard to remove could delay treatment. Specifications are left to the combination product developer to set and justify, based on human factor and engineering studies.

- Activation Force The activation force is the force required to initiate drug dispensing when the device is pressed up against the patient’s skin. This force results in actuation of the spring that drives the drug dispensing piston. Similarly to cap removal force, an activation force outside the pre-determined range could delay drug delivery and/or cause medication errors and is therefore a primary function. Specifications are left to the combination product developer to set and justify, based on human factor and engineering studies.

- Injection Time If the injection time is too long, the user may withdraw the device prematurely, which would result in an incomplete dose. If the injection time is too short, the drug may not have the opportunity to disperse quickly enough under the patient’s skin and this could result in pain or leakage. An injection time outside the pre-determined specification may cause unacceptable harm to the patient. Specifications are left to the combination product developer to set and justify, based on human factor and engineering studies.

- Dose Accuracy The delivery of the correct dose to the patient is a primary function of the auto-injector. The specification range is to be set by the drug manufacturer based on the dosing requirements.

- Extended Needle Length The drug needs to be delivered to a specific subcutaneous or intramuscular location and injection depth control is part of correct route delivery, which is a primary function of the auto-injector. The specification range is to be set by the drug manufacturer based on physiological considerations and/or studies.

- Needle Guard Lockout While the failure of the needle safety mechanism would not impact a primary function of the device, ISO 11608-5:2022 requires needle shielding after injection to be compliant with ISO 23908:2011 Sharps injury protection — Requirements and test methods — Sharps protection features for single-use hypodermic needles, introducers for catheters and needles used for blood sampling5. ISO 11608-5:2022 specifies that the force required to override the needle guard lockout must be at least twice the set maximum activation force for the same device.

Execution of the above verification tests can be an onerous activity involving a series of individual steps unless one invests in specialized testing equipment that is designed to perform each of the above tests, in sequence, on a single auto-injector.

Manufacturers of mechanical testing machines have developed add-ons that can start with a single auto-injector, measure the cap removal force, activate the auto-injector while measuring the activation force, time the drug delivery period, measure the delivered drug product mass, quantify the needle length, activate the needle guard, and record the needle guard lockout override force.

West’s Analytical Laboratory Services (ALS) has extensive experience with performing this type of automated auto-injector testing. Not only does West ALS have expertise in testing West’s SelfDose patient-controlled injector, but, being an independent analytical laboratory, they also have expertise in testing auto-injectors developed by other device manufacturers, such as Ypsomed’s YpsoMate™ series of devices.

In addition to testing outright device performance, ISO 11608-1:2022 also presents a matrix of pre-conditioning that samples need to be subjected to before performing this type of testing in order to assess the robustness of the combination products, including cool/standard/warm storage conditions, free-fall exposure, dry-heat storage, cold storage, vibration exposure, transport conditioning (per ASTM D4169-226) and shelf-life stability. Demonstrating this type of robustness is required to assure that the auto-injector will be ready to perform when the patient needs it. West ALS can facilitate pre-conditioning and stability studies to help clients establish the robustness and performance of their combination products. Contact West to learn more about how we can help you with your auto-injector testing needs.

References

- Vijayaraghavan, R. Auto-injector device for rapid administration of drugs and antidotes in emergency situations and in mass casualty management. J Int Med Res. 2020 48(5) 1-12. https://pubmed.ncbi.nlm.nih.gov/32436421/

- United States. Food and Drug Administration. Guidance for Industry and FDA Staff: Technical Considerations for Pen, Jet, and Related Injectors Intended for Use with Drugs and Biological Products. U.S. Department of Health and Human Services, 2013.

- International Organization for Standardization. (2022). Needle-based injection systems for medical use — Requirements and test methods — Part 5: Automated functions (ISO Standard No. 11608-5:2022). https://www.iso.org/standard/76627.html

- International Organization for Standardization. (2022). Needle-based injection systems for medical use — Requirements and test methods — Part 1: Needle-based injection systems (ISO Standard No. 11608-1:2022). https://www.iso.org/standard/70733.html

- International Organization for Standardization. (2011). Sharps injury protection — Requirements and test methods — Sharps protection features for single-use hypodermic needles, introducers for catheters and needles used for blood sampling (ISO Standard No. 23908:2011). https://www.iso.org/standard/50680.html

- ASTM Standard D4169, 2022, " Standard Practice for Performance Testing of Shipping Containers and Systems," ASTM International, West Conshohocken, PA, 2022, https://www.astm.org/d4169-22.html.