Optimizing Primary Packaging for Injectable Drugs: Ensuring Safety, Efficacy, and Quality - Part 1

The primary packaging of injectable drug products plays a critical role in ensuring the safety, efficacy, and quality of the drug products. In this blog, we will explore the key considerations and methodologies involved in selecting the optimal primary packaging components for injectable drug products to ensure patient safety.

Selecting the appropriate primary packaging involves careful consideration of various factors, which are listed below:

- Regulatory requirements related to packaging components

- Compatibility of packaging components with the drug formulation

- Protection from extractables & leachables

- Design of packaging components

- Container closure integrity testing considerations

- Packaging components preparation methods & specifications

- Sterilization process of the packaging components

- Documentation & Services

Regulatory requirements related to packaging components:

The regulatory landscape for packaging components in the pharmaceutical industry is shaped by several key standards and guidelines that are applicable to the drug manufacturers, including USP <382 > (effective from 01 Dec 2025), EU GMP Annex 1, and the EU Medical Device Regulation (MDR) 2017/745.

USP <382> focuses on the functional suitability of elastomeric components in parenteral product packaging/delivery systems, emphasizing the functionality evaluation of entire systems rather than isolated components to ensure fitness for intended use. This approach aims to enhance patient safety by reducing risks through comprehensive product understanding.

EU GMP Annex 1 provides guidelines for the manufacture of sterile medicinal products, highlighting the importance of aseptic processing and contamination control strategies. It emphasizes the need for validated cleaning processes to control particulate, endotoxin, and bioburden contamination, several sections within EU GMP Annex 1 highlights how the packaging components have to be prepared and the importance of CCI testing is emphasized as well.

The EU MDR, on the other hand, sets out requirements for medical devices, including prefilled syringe as a single integral product, to ensure safety and performance. It mandates rigorous testing and documentation to demonstrate compliance with General Safety and Performance Requirements (GSPRs), thereby ensuring safety and performance of the device part. Together, these regulations underscore the critical role of packaging components in maintaining the integrity and safety of pharmaceutical products.

Compatibility of packaging components with the drug formulation:

Ensuring compatibility between the drug formulation and the packaging components is critical in developing injectable drug products. This compatibility determines whether the packaging materials can protect the drug's integrity over its intended shelf life without interacting in harmful ways. Adverse interactions can negatively impact the drug, leading to deterioration of the product, which may manifest as drug degradation, a loss of efficacy, or even the formation of toxic by-products. Hence, understanding and evaluating the compatibility of packaging components with the drug formulation is a priority in packaging selection.

Compatibility involves both chemical and physical interactions between the drug and packaging materials. Chemical interactions might include reactions between the drug and the material or additives used in packaging. These can alter the drug's chemical structure, affecting its potency or creating harmful side products. Physical interactions might involve the adsorption or absorption of the drug or its excipients onto or into the packaging material. Adsorption refers to the accumulation of molecules on the surface of the packaging material, while absorption involves the penetration of these molecules into the material's bulk. Such occurrences can lead to a reduction in the drug's availability for therapeutic action, potentially resulting in dosing inconsistencies. To ensure robust compatibility, rigorous compatibility studies are conducted. These studies systematically evaluate whether the materials of construction of the packaging components can withstand several factors such as solvent composition, pH variations, viscosity, and drug potency without compromising product quality. Throughout these studies, special attention is also given to the adsorption or absorption processes.

Ensuring compatibility involves a multifaceted approach of conducting comprehensive studies to evaluate potential interactions under varied conditions representative of manufacturing, storage, and usage environments. This rigorous evaluation is vital to the drug's safety, efficacy, and quality throughout its lifecycle, protecting both the investment in drug development and, most importantly, the well-being of patients.

Protection from extractables & leachables:

Extractables are compounds extracted from packaging materials under aggressive laboratory conditions, while leachables migrate into the drug product under normal storage and usage conditions. Comprehensive Extractables & Leachables (E&L) testing, involving advanced analytical techniques, is essential to identify and quantify these compounds, ensuring they remain within safety thresholds in drug products. Selecting packaging components known for their material compatibility is a key strategy in mitigating E&L risks. FluroTec™ barrier film technology exemplifies this approach with its proprietary fluoropolymer film, providing a robust barrier in elastomeric packaging components like vial stoppers and syringe plungers. FluroTec™ barrier film is known for its chemical non-reactivity, enhanced barrier properties, and reduced particulate contamination, all of which safeguard the purity and stability of the drug product throughout its shelf life. Beyond maintaining these protective features through various sterilization processes, drug products with FluroTec™ barrier film stoppers & plungers are widely recognized and accepted by regulatory bodies, facilitating compliance and approval. Through these solutions, pharmaceutical companies can uphold high standards of product quality and patient safety, paving a smoother path through regulatory landscapes.

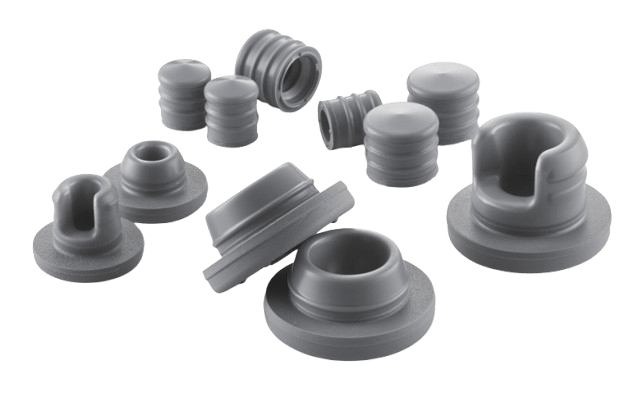

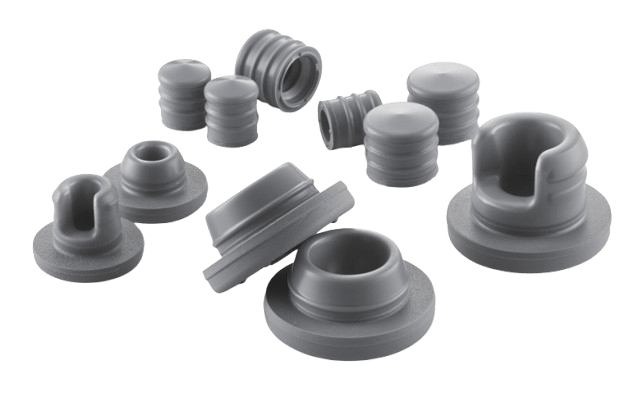

Design of packaging components:

The design of packaging components for injectable drug products is a critical aspect that directly influences drug stability, user experience, and overall product safety. Effective design goes beyond simple containment; it also involves optimizing the packaging for functionalities such as drug protection and administration suitability.

Serum stoppers are used for liquid injectable formulations, where their primary role is to maintain a sterile barrier while allowing for easy administration and must allow for smooth, single or multiple puncture entries by hypodermic needles without fragmentation or coring. After puncture, they should reseal effectively to prevent leakage, which is essential for multi-dose vials.

Design for manufacturability (DFM) is a crucial consideration for stoppers, specifically lyophilization (lyo) stoppers, due to the complex nature of the lyophilization process. Lyo stoppers play a pivotal role in ensuring a successful freeze-drying process, and several specific factors highlight why DFM is particularly important for these components. Lyo stoppers are designed to perform distinct roles during different phases of the lyophilization process, such as allowing moisture escape during drying and sealing the container post-process. These dual functionalities require a sophisticated design that accommodates precise motion and reliable sealing. DFM ensures that these complex designs can be consistently manufactured within tight tolerances, thus maintaining functionality and reliability across large production volumes. In pharmaceutical manufacturing, achieving high-quality, repeatable processes that meet stringent regulatory standards is contingent upon meticulous process design and skilled manual intervention. The DFM approach considers how lyo stoppers will be handled and processed by automated systems. This ensures that stoppers are designed in a way that enhances alignment, placement, and sealing efficiency, reducing manual intervention and error rates.

NovaPure® brand is West’s premier line of stoppers, offering the most stringent particulate specifications among West elastomer products. These stoppers seamlessly integrate the protective advantages of FluroTec™ barrier film, the precision of the West Envision™ verification process, and comprehensive lot-to-lot extractables testing. Our dedication to Quality by Design (QbD) principles ensures deep process understanding and meticulous manufacturing controls, resulting in a product that consistently meets the demands of today’s delicate, high-value biologics and small molecules. Available for serum lyophilization applications, NovaPure® stoppers exemplify reliability and performance in challenging pharmaceutical environments.

Designing the primary packaging components for drug delivery devices involves a comprehensive understanding of the functional requirements, material properties, user interaction, and regulatory compliance. Unlike vial containment systems, drug delivery devices often have integrated functionalities that aid in the administration of the drug, ensuring accuracy, ease of use, and safety for the patient. The design of NovaPure® plungers are centered around optimizing performance and ensuring high-quality standards for drug delivery devices, particularly in prefilled syringes and auto injectors. NovaPure® plungers are developed using QbD principles, which ensure a systematic, science-based approach to manufacturing. This results in optimized break loose and glide forces, low part-to-part variation, and high-quality performance. These design features and advantages make NovaPure® plungers a preferred choice for pharmaceutical companies aiming to enhance the safety, efficacy, and reliability of their drug delivery systems.

As we conclude our exploration of regulatory requirements, compatibility, protection from extractables and leachables, and the design of packaging components, stay tuned for the second part, where we will delve into considerations such as container closure integrity testing, preparation methods and specifications, sterilization processes, and documentation services.