Ensuring Sterility to Meet the Revised EU GMP Annex 1 Regulations

Ensuring the sterility of medicinal products has always been one of the key concerns of drug manufacturers, due to the dire health implications it could have on patients, as well as the potential for costly product recalls. The importance of control strategies to ensure drug products remain sterile has also been reiterated recently by regulatory agencies such as the U.S. Food and Drug Administration (FDA) and The European Medicines Agency (EMA) in their respective guidelines:

- FDA: Sterile Drug Products Produced by Aseptic Processing – Current Good Manufacturing Practice

- EU GMP Annex 1 Manufacture of Sterile Medicinal Products

The revised EU Good Manufacturing Practice (GMP) Annex 1 has evolved to improve public health. Specifically, the change has introduced a more unified version of guidelines for the manufacturing of sterile medicinal products, with the key objective to remove ambiguity, but more importantly, open a dialog between regulators and the pharmaceutical manufacturer and their critical suppliers.

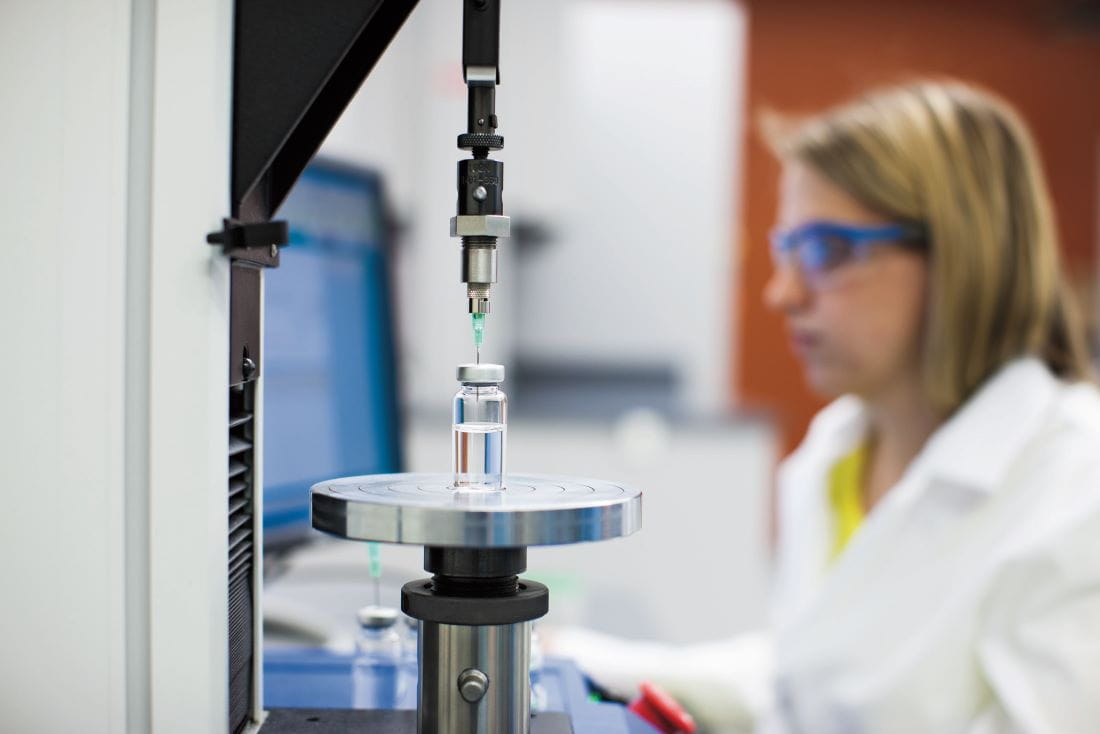

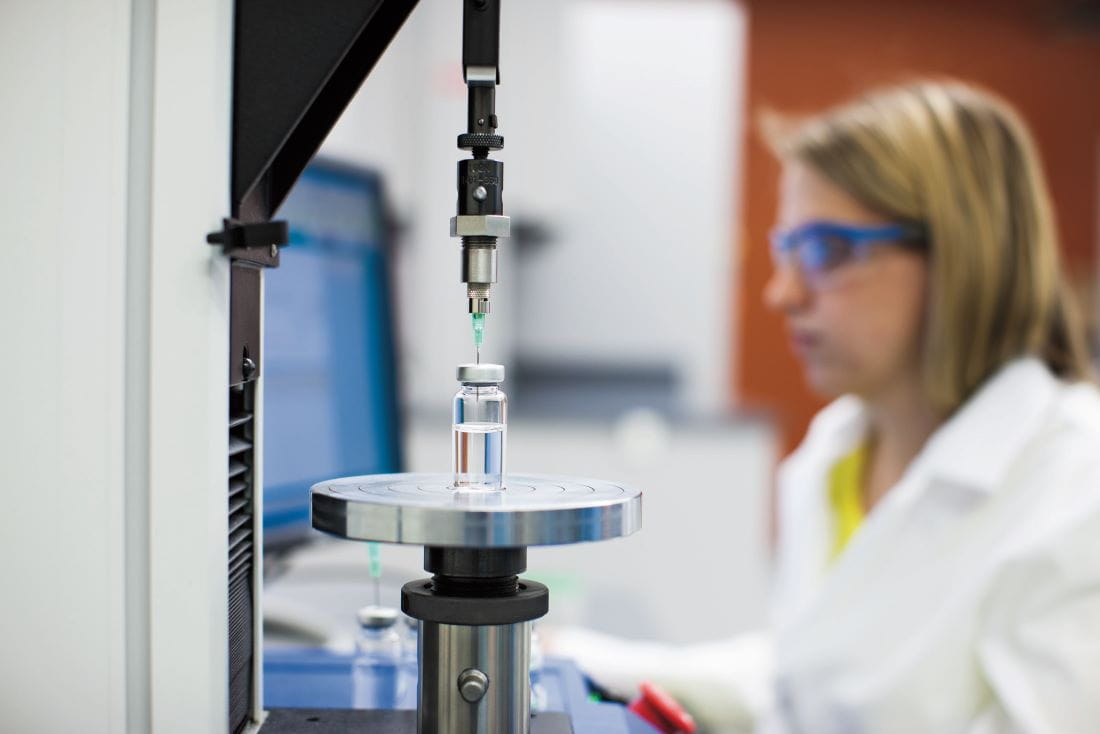

With this revision, the regulations have more than tripled in length, and they contain over 30 references to primary packaging material alone, including implementing a holistic Contamination Control Strategy (CCS) and the recommendation for use of modern barrier technologies, such as RABS and isolators, to reduce the risk of contamination. A second key theme is container closure integrity (CCI) that challenges manufacturers to have a firm understanding of the factors that impact CCI and set out methods of monitoring and testing.

In both guidance’s, sterile products entail minimal risks of particulate, endotoxin, and microbial contamination. Particulate and microbial contamination is minimized with the implementation of high-quality environmental conditions for different stages of the manufacturing process. This could be achieved with the use of clean rooms of the appropriate class (ISO class 5 to 8) or even restricted access barrier systems (RABS) and isolator systems in the case of aseptic processing. However, additional control measures are still needed for further reduction of endotoxin and microbial contamination. This involves adequate depyrogenation and sterilization processes.

For containers and closures, one common depyrogenation technique involves the use of Purified Water, USP or Water for Injection (WFI) to rinse the containers or closures over multiple cycles prior to sterilization. Regardless of the technique utilized, the depyrogenation process should be validated to meet a 3-log reduction in endotoxin content.

Sterilization of Elastomers

To ensure sterility, a sterility assurance level (SAL) of 10-6 or better is attained to qualify the sterilization cycle. Validation studies are carried out to ascertain the effectiveness of the sterilization process, followed by periodic requalification studies. Depending on the stability of the parenteral packaging material and drug product, different sterilization techniques could be used. This includes moist heat, dry heat, radiation, ethylene oxide and filtration techniques.

Parenteral Packaging Components

One example is the NovaPure® Ready to Sterilize (RS) and Ready to Use (RU) brands of elastomeric components that are delivered to customers to mitigate risk when protecting lyo and liquid drugs from visible, subvisible particulates and unwanted stopper interactions. Such products have undergone a validated pharmaceutical wash process that allows them to meet the specified limits for bacterial endotoxin, bioburden, particulate matter. Importantly, a 3-log reduction in the endotoxin content is also ascertained during the validation study for the pharmaceutical wash.

NovaPure RU elastomeric components further simplify the downstream processing at the pharmaceutical company as these components are delivered as ready-to-use and have already been sterilized by steam sterilization or gamma irradiation (validated to achieve SAL of 10-6 or better) after undergoing the validated pharmaceutical wash process. A Quality Certificate will be provided with the following product specifications – sterility assurance (only for steam sterilization; for gamma irradiated components, gamma dose range is reported), particulate matter content, bacterial endotoxin levels, silicone level (when applicable) and residual moisture (lyophilization stoppers only).

EU GMP Annex 1 - Vial Capping

In recent years, the EU GMP Annex 1 “Manufacture of Sterile Medicinal Products” has included the vial capping conditions required for both aseptic and clean processing. While sterilized caps / seals must be used in an aseptic process, the seal grade was not stipulated for the clean process, as long as crimping is performed in a grade A environment. West has thus developed Flip-Off® CCS seals to meet such stringent regulatory requirements, with sterilization fulfilled by gamma irradiation.

West’s Flip-Off® CCS (Clean, Certified, Sterilized) seal, as suggested by its name, is a high-quality sterile seal that is provided primarily in an RU grade. These sterilized seals are developed for aseptic crimping in a grade A environment. Some key benefits include reduced abrasion driving lower particulate levels through an aluminium shell coating. The seals offer low particle and low bioburden levels before sterilization as they are assembled in an ISO 8 environment.

While glass is commonly used in the drug containment system such as vials or prefilled syringes, they may be incompatible with high and low pH drug products that could result in glass delamination as well as a compromised container closure integrity under cryogenic storage. Thus, West offers Daikyo Crystal Zenith® (CZ) cyclic olefin polymer containers for such drug products. CZ containment solutions are provided as bulk non-ready-to-use format, and ready-to-use format, which is sterilized by a validated e-beam sterilization process (SAL of 10-6 or better).

Packaging for parenteral packaging components

It is imperative to understand the sterilization and subsequent use of these components in the pharmaceutical facility, especially in aseptic processing, so West offers the validated STERILIZABLEBAGTM packaging system to contain RS and RU components. This packaging system consists of the Tyvek® 1073B packaging material and a multi-layered polyethylene film. While the Tyvek® 1073B [1] packaging material allows steam permeation, it also acts as a barrier to prevent bacterial ingress, thereby helping to ensure sterility. The multi-layered polyethylene film on the other hand helps to maintain the package integrity after sterilization, shipping and throughout the product shelf-life.

With the introduction of restricted sterile systems such as isolator / RABS in aseptic processing, it is important to ensure that the parenteral packaging components could be aseptically transferred to the filling line. To meet such a requirement, West also offers the choice of RS or RU components filled in port bags. These port bags are Biosafe® bags and DPTE® BetaBags from Sartorius Stedim Biotech and GETINGE, respectively, which could undergo steam sterilization or gamma-irradiation. Such bags contain a beta port that could connect to the alpha port of restricted sterile systems that will facilitate the aseptic transfer of the parenteral packaging components.

Having a holistic understanding of supplier component production through to pharmaceutical drug production is at the heart of innovation at West. This innovative mindset ensures products are available to help pharmaceutical manufacturers meet ever-increasing regulations, such as the revised EU GMP Annex 1.

For a deeper dive into selecting container closure components with confidence: A data-driven approach to CCI, read more here.

For an overview of EU GMP Annex 1 challenges, considerations and solutions, please click here

Westar, Flip-Off, and STERILIZABLEBAG are trademarks or registered trademarks of West Pharmaceutical Services, Inc. in the United States and other jurisdictions.

Crystal Zenith is a trademark of Daikyo Seiko, Ltd. Crystal Zenith technology is licensed from Daikyo Seiko, Ltd. All other trademarks appearing here are the property of their respective trademark owners.