Steam-Sterilized Components with FluroTec® Barrier Film Technology May Aid Biosimilars

Many of the top-selling biologic drug products will soon come off-patent. As a result, according to IMS, the biosimilar market is expected to reach between US$1.9-2.6 billion by 2015.

![]()

A biosimilar is a biological drug product that is similar to a previously approved brand name biologic. Typically, the differences are found in clinically inactive components, which result in little or no difference between the biosimilar and the approved biological product currently on the market in terms of safety, purity and efficacy. Many companies are activity working to develop and commercialize biosimilars.

One of the ways companies developing biosimilars will differentiate new products in similar therapeutic categories is to change the injection format and method of delivery. For many companies, the decision to select a prefilled syringe system rather than a branded vial format is strategic because it meets the demands of physicians and patients looking for easier modes of administration. Also, the syringe can be supplied in an auto-injector format for self-injection convenience.

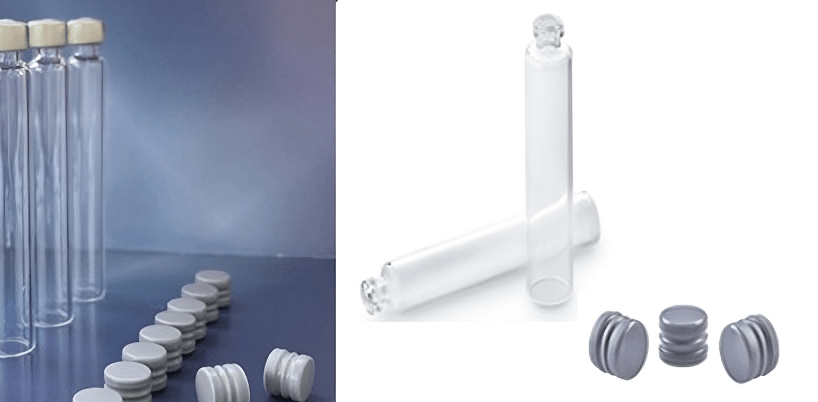

Proper selection of plunger component materials in a ready-to-use format is critical to drug performance in a prefilled syringe. FluroTec closure technology, which is available for modern elastomer formulations for stoppers and plungers, is the leading choice of barrier film for components used with biologic drug products. FluroTec film provides an effective barrier against organic and inorganic extractables, minimizing interaction between the drug and the plunger. The fluorocarbon film also reduces absorption and adsorption of biologics, an important benefit for maintaining the safety and purity of products during shelf life.

Historically, the market has used gamma-sterilized plungers for syringe systems and steam-sterilized stoppers for vial systems. Selecting a steam-sterilized plunger can lower risks for biosimilars intended for a prefilled syringe format. Using a steam-sterilized plunger with FluroTec barrier film against an equivalent elastomer formulation used for vial stoppers can significantly reduce risks associated with extractable and leachable profiles, provide higher assurance for successful long-term stability to meet shelf-life requirements and can be leveraged in drug approvals since the materials are market proven and well recognized by regulatory agencies.

For biosimilar manufacturers, speed to market is key to gaining a strong market share, so a decision to match component technology to proven vial formats may be less risky. West offers several steam-sterilized plunger products, including Westar® ready-to-useplungers and our primary recommendation, NovaPure® ready-to-use plungers. Selection of these components early in the development process may move a biosimilar to market faster while ensuring that the drug product’s safety and efficacy is not affected by the change in packaging materials or sterilization modes.

FluroTec®, NovaPure® and Westar® are registered trademarks of West Pharmaceutical Services, Inc., in the United States and other jurisdictions.

FluroTec technology is licensed from Daikyo Seiko Ltd.