Filling the Gap with 1.5 mL FluroTec® Plunger for Cartridge-based Technology

The global pen injector and auto-injector markets have witnessed significant growth due to the increasing demand for self-administration of injectable drugs. Pen injectors and auto-injectors provide a user-friendly and convenient solution for patients to administer medications, contributing to improved patient compliance and overall healthcare outcomes. There are well established traditional market segments that use cartridge-based delivery systems, including dental local anesthesia and diabetes care, as well as human growth hormone and allergy therapies. However, there have been significant developments in the incorporation of cartridges in auto-injectors as supposed to the traditional syringe designs.

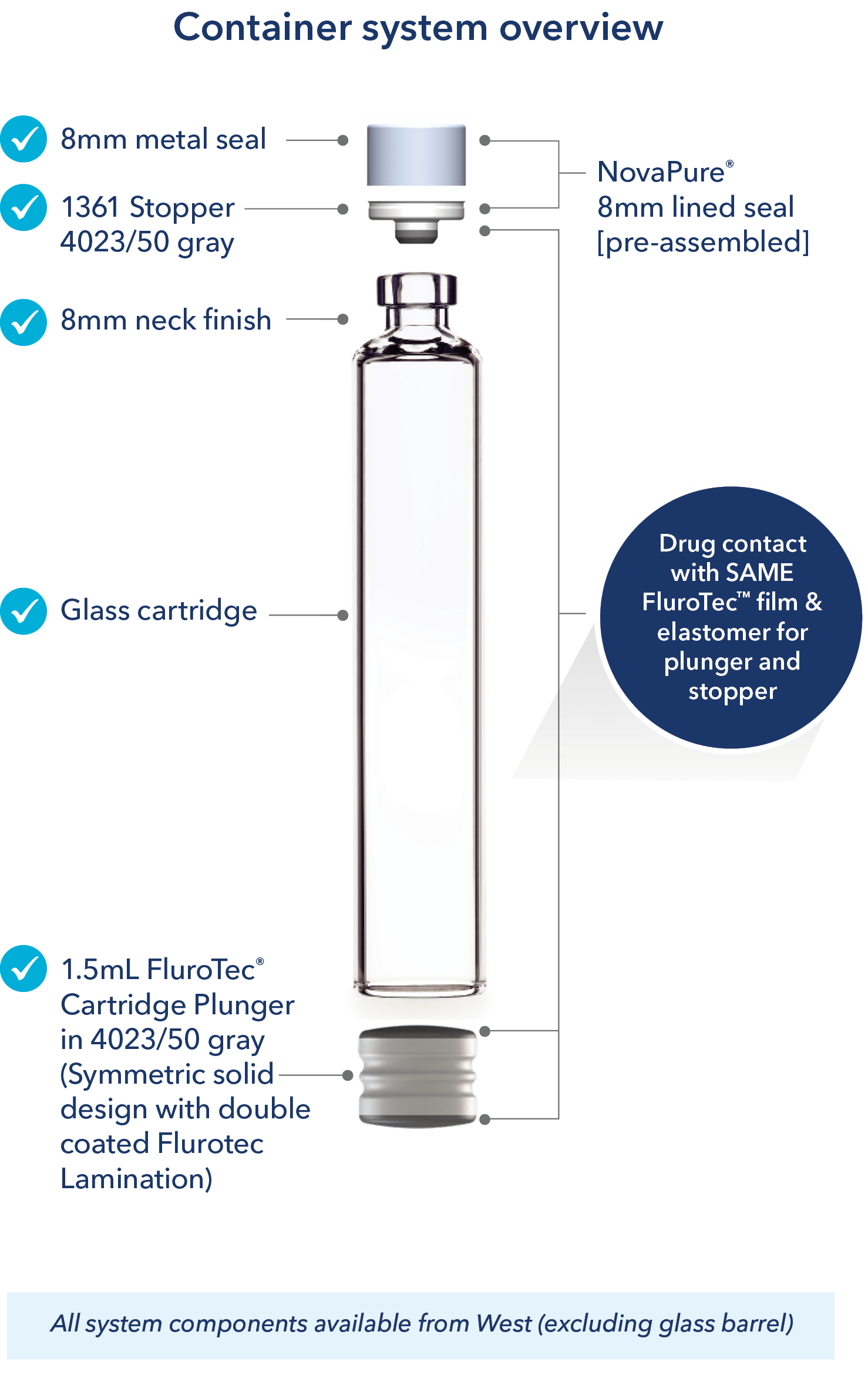

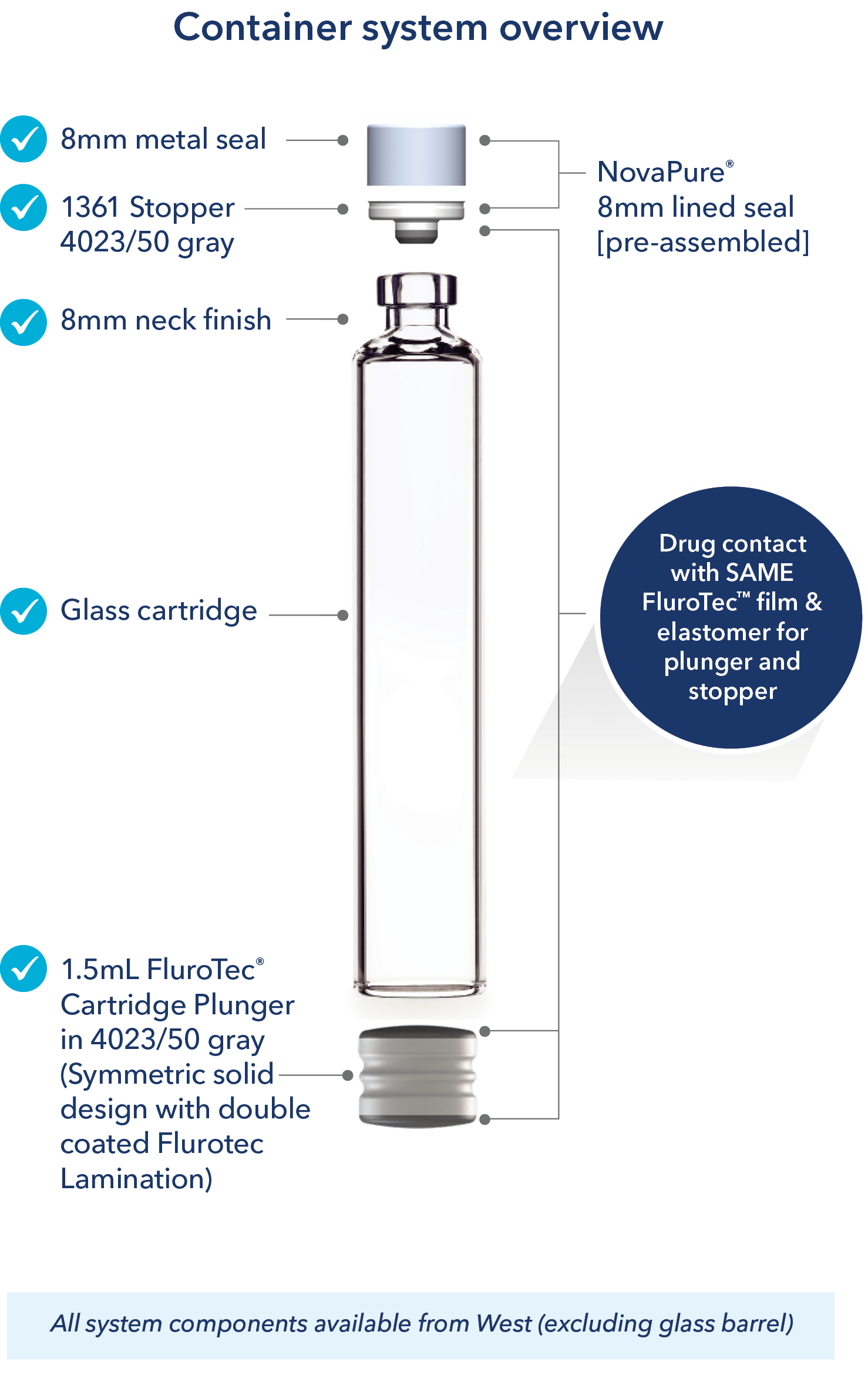

The traditional markets will continue to maintain much of the volume for cartridge-based systems in the future; however, there is a rising demand for self-administration in other therapeutic classes of drugs influenced by the expanding use of biologics and specialty drugs, which often require precise and controlled delivery methods. Auto-injectors play a crucial role in the administration of these complex therapies, ensuring accurate dosing and reducing the risk of errors associated with manual injections. There are additional benefits for companies working on lifecycle management by selecting one platform of FluroTec™ barrier film-laminated components in rubber formulation 4023/50 grey across different container formats (cartridges, vials, prefilled syringes). West offers serum and lyophilization stoppers as well as syringe and cartridge plungers and 8 mm lined seals from the same elastomer formulation and with FluroTec barrier film lamination on the drug contact side.

The FluroTec® 1.5 mL cartridge plunger, combined with the recommended lined seal designed in accordance with industry standards for single dose or multi-dose applications, helps open the small volume self-management market. The West laminate technology for lined seals is best-in-class and leverages an 8 mm NovaPure® seal with a laminated stopper. Having the same drug contact materials on the plunger and the lined seal, which is the case for a cartridge being assembled with West NovaPure® 8mm lined seal and the FluroTec 1.5 mL cartridge plunger, both in rubber formulation 4023/50 gray, simplifies development.

The primary cartridge system consists of three container components:

- Cartridge container – glass (majority)/plastic

- Cartridge plunger – elastomer material

- Cartridge Lined seal – metal cap and a rubber disk.

The use of traditional cartridge components could lead to challenges; one challenge could be that existing plunger and seal technology for cartridges were developed for less complex drug molecules and do not meet the evolving requirements for drug delivery, especially for drug compatibility.

In response to the market needs for plunger technology designed especially for small volume injectors, West has developed the FluroTec® 1.5 mL film-laminated cartridge plunger.

The FluroTec 1.5 mL cartridge Plunger is symmetric and designed with double sided Fluro- polymer film to help simplify drug development, shorten development time, and streamline manufacturing, pharmaceutical manufacturers are trending toward ready-to-use (RU) containers and components.

Key features of FluroTec® 1.5 mL cartridge plungers are:

- Symmetric double sided FluroTec® film lamination on the drug contact side

- Elastomer formulation 4023/50 Gray elastomer (Bromobutyl)

- B2-coating on the outer surface

- Westar® Ready to Use (RU) steam sterilized

- Designed to be used with glass cartridges.

FluroTec® film-laminated cartridge plunger meets the increasing standard of modern drug products by reducing the risk of drug compatibility issues and rework in component qualification, and by reducing the risk of drug adsorption and absorption. This transparent proprietary fluoropolymer film is laminated on the product contact face of the plunger to provide a physical barrier and reduce possible interactions between the elastomer and the drug and limiting potential plunger leachable into the drug product, thereby reducing the potential of contaminants which may impact drug efficacy and safety. FluroTec technology has been proven in many commercial applications on the global pharmaceutical market.

The FluroTec 1.5 mL cartridge plunger was developed with a bromobutyl elastomer formulation named 4023/50 Gray. This compound is a clean elastomer formulation with well-characterized extractables and volatiles, supported by West’s extractables material characterization packages.

The plunger is coated with a proprietary B2-coating on the plunger ribs for lubricity, to support good functionality and helps smoothly transporting, orienting, and inserting the components with filling machine equipment.

Component processing is a source of risk and variability, especially for loose particulate and silicone oil that can compromise quality, putting patients at risk. Pharma companies can simplify drug development strategy and streamline manufacturing by selecting Westar cartridge plungers and NovaPure lined seals in Ready-to-Use (RU) format. The utilization of Westar® and NovaPure RU products provides customers with increased WFI and Sterilization capacity, eliminates the need for any parenteral packaging component preparation, and provides just-in-time flexibility which helps to manage efficient sterile fill campaigns. The Westar™ and NovaPure washing technology and the steam-sterilization process are supported by Drug Master Files (DMFs) with the FDA and Health Canada and have tight particulate specification and AQL simplified regulatory strategy, pharmaceutical wash and steam sterilization program and a Type -V DMF.

The FluroTec 1.5mL cartridge plungers has been designed to be used with a glass cartridge with an internal diameter of 6.85 ± 0.1 mm; described in ISO 11040-4:2015. The symmetric design eliminates the need of plunger orientation on the filling machine and facilitates the implementation by using existing filling equipment.

A performance study was performed with assembled glass cartridges by using FluroTec® 1.5mL 4023/50 grey plungers and a lined seal. The plunger has a symmetric shape with double side FluroTec™ barrier film laminations, however a trim edge creates the sealing area on one side of the plunger, while all other sealing lribs are molded. Plungers were inserted in two positions: trim edge up and trim edge down to evaluate if there is an impact of plunger orientation. Beside the orientation, components have been exposed to one or two steam sterilization cycles.

The study included tests of initiating and sustaining forces analysis, helium leak detection analysis, and freedom from leakage analysis. Tests were performed at ambient storage conditions (23°C ± 3°C) at time points 0, 6, 12 and 24 months. Results through 12 months show all combinations were within specification for each respective test:

- Container Closure Integrity (CCI) Helium leak detection [100% Helium flow]: All Helium leak rates were far below the Kirsch limit for all test points, there were no discernable differences seen with orientation or sterilization of the plunger; the results are on average one thousand times lower than the Kirsch limit.

- Initial & Sustaining Force: All forces observed were well below the acceptable ISO standard maximum forces over time; there were no discernable differences seen with orientation or sterilization of the plunger.

- Fluid Leakage: No leakage observed; there were no discernable differences seen with orientation or sterilization of the plunger.

Results from the 0-, 6- and 12-month time points were within specification for each respective test. There were no discernable differences seen with orientation or sterilization of the plunger. Data collection at 24 months is still in process.

Westar RU steam plungers have been shown to demonstrate optimal performance characteristics when assessed in standard glass cartridges.

For additional information on FluroTec 1.5 mL cartridge plungers click here or contact an account representative today.

References:

- West Technical Report 2023/267 FluroTec® 1.5 mL Cartridge Plunger Performance

- ISO 13926-2:2017, Pen systems — Part 2: Plunger stoppers for pen-injectors for medical use - ISO 11608-3, Needle-based injection systems for medical use — Requirements and test methods — Part 3: Containers and integrated fluid paths, 2012 & 2022 versions

- ISO 13926-2:2017, Annex A, “Leakage test”

- Enabling greater homecare through innovative large volume on-body delivery systems, February 8, 2023, Victoria Morgan

- Trends in drug delivery – the growth of cartridge-based technology, September 9, 2015, Royce Brocket

West and the diamond logo and FluroTec are trademarks or registered trademarks of West Pharmaceutical Services, Inc. in the United States and other jurisdictions. FluroTec and B2-coating technology is licensed from Daikyo Seiko, Ltd.

Copyright ©2023 by West Pharmaceutical Services, Inc.All rights reserved.

This material is protected by copyright. No part of it may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying or otherwise, without written permission of West Pharmaceutical Services, Inc.