The Importance of Characterizing the Extractable and Leachable Profile of Stoppers for Drug Stability

In the pharmaceutical industry, safety and quality are paramount. One critical aspect of ensuring the safety of pharmaceutical products is extractables and leachables (E&L) testing. This testing process examines the potential migration of substances from containers, packaging materials, and drug delivery systems into the drug products themselves. By understanding the reasoning behind E&L testing, we can appreciate its role in protecting public health and enhancing customer trust. West Pharmaceutical Services, Inc. is a leader in developing comprehensive studies to evaluate container closure systems in real world simulations, providing customers with a better understanding of their leachable profile and how that could affect drug stability.

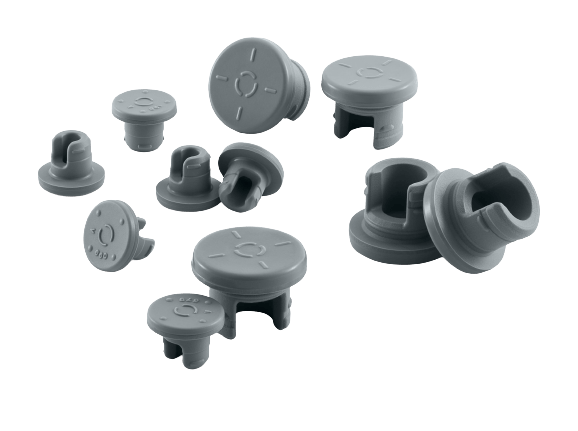

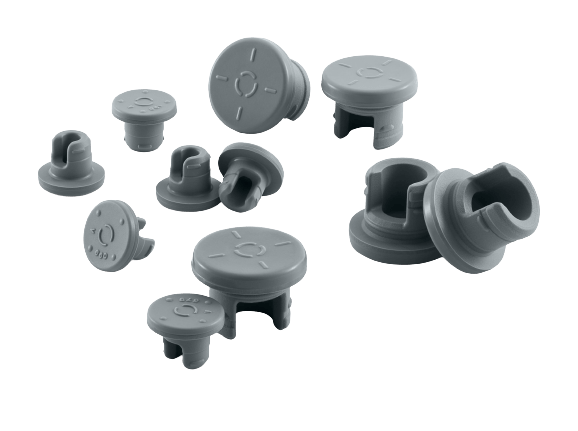

Many types of packaging materials are involved in the production and containment of drug products, such as the elastomeric closure, vials, or another containment device. Each of these items may impact the drug product over time. The typical process of evaluating E&L begins with identifying the extractables, which are chemical compounds that can be released from containers, closures, and packaging materials under exaggerated or extreme conditions. While extractable testing is a necessary starting point, it does not provide all the required information to determine drug compatibility. Therefore, further testing is needed to investigate leachables, which are the subset of extractables that migrate into the drug product under normal conditions. In an ideal situation, the only leachable compounds detected in a drug are compounds present in the extractables profile, however, the leachable profile can contain additional compounds. These additional leachables can be the result of environmental influences or reactions between compounds and the drug, generating new compounds not previously detected.

The significance of E&L testing lies in its ability to identify potential risks associated with the use of containers and packaging materials in the pharmaceutical industry. While all packaging materials and elastomer formulations contain extractables, these materials can be subjected to rigorous testing to assess the likelihood and extent of leaching of specific compounds. This enables manufacturers to make informed decisions regarding product safety. Understanding the leachable profile allows manufacturers to evaluate potential drug interaction with degradants and reactants that could lead to patient harm or cause drug instability. Another consideration is whether to use a barrier film or non-laminated stopper. Stoppers with a barrier film applied to the plug side of the stopper, like West’s FluroTec™ film, can reduce the number of leachable compounds. If the E&L profile is known, the drug manufacturer can make an informed decision on whether the barrier film is necessary for drug stability or if a non-laminated stopper would be sufficient. An understanding of the overall extractables profile is helpful in early stages of drug development to align with Quality by Design (QbD) requirements and guide the manufacturer in selecting components that will not lead to negative downstream effects.

Common industry approaches to detect and identify the greatest number of E&L compounds utilize a combination of chromatography and mass spectrometry for both direct injection and headspace analyses. West has implemented a series of orthogonal techniques using liquid and gas chromatography to identify a broad range of volatile, semi-volatile, and non-volatile compounds. Implementing these methods in an E&L study over time is critical as compounds will migrate at different rates, meaning that the leachable profile will change throughout the shelf life of the drug product.

This is the approach that West has taken to characterize our newest formulation, 4040/40 Gray. The 4040/40 formulation was developed through a QbD approach with reducing leachables in mind, leading to the formula containing less leachable compounds at reduced concentrations, as well as the removal of the BHT and other compounds. This is shown through a comparative leachables simulation with time points taken at various points. The study evaluated how the extractables, detected in the material characterization study, migrated and became leachable compounds in a placebo lyo cake. An overview of the methodology and results for this study can be found in the Technical Report 2022/253 “The Impact of a QbD Approach: A Comparative Evaluation of Different Stoppers in a Simulated Leachables Data Model”, located in the West Knowledge Center*. As the 4040/40 platform grows and serum stoppers are developed, further E&L studies will be conducted to show how the application of the stopper impacts the leachable profile. Learn more about 4040 LyoTec® stoppers by clicking here.

Extractables and leachables testing plays a pivotal role in the pharmaceutical industry, safeguarding public health and ensuring the safety and quality of drug products. By understanding the background, understanding the importance, and understanding the benefits it offers to customers, we can appreciate the critical nature of this testing process. As pharmaceutical companies continue to innovate and develop new therapies, E&L testing will remain an indispensable component in maintaining safety, regulatory compliance, and customer satisfaction. West is committed to utilizing 100 years of experience and exposure to aid our customers in the complicated field of leachables testing.

For more information on the importance of extractables and leachables related to the 4040 LyoTec® stoppers, please contact your Technical Customer Service representative.

*Knowledge Center Account required for access

FluroTec and LyoTec are trademarks or registered trademarks of West Pharmaceutical Services, Inc. in the United States and other jurisdictions.

FluroTec technology is licensed from Daikyo Seiko, Ltd.